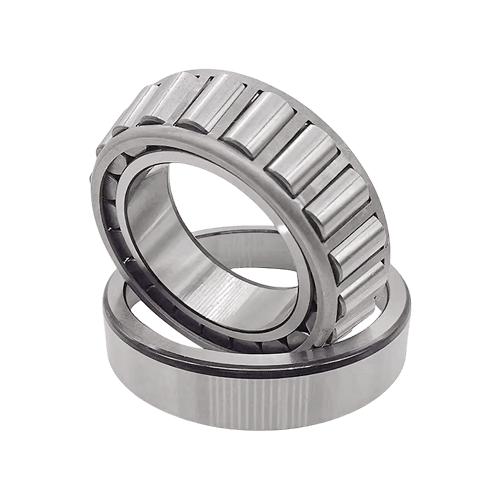

Tapered roller bearings

Tapered Roller Bearings (TRBs) excel in high loads, high speeds and complex working conditions due to their unique design structure. Their structural characteristics enable them to withstand both axial and radial loads, so they are widely used in industrial equipment that needs to withstand multi-directional loads.

1. Product Features

Strong load-carrying capacity: Tapered roller bearings are designed with tapered rolling elements, which enable the bearings to withstand both radial and axial loads. This design enhances the load carrying capacity and makes it more reliable in complex working conditions.

Adjustability: The relative position between the inner and outer rings of tapered roller bearings can be adjusted, which allows the radial and axial clearances of the bearings to be precisely adjusted as needed to meet the load requirements of a particular application.

High temperature resistance and high load performance: this type of bearing can still maintain good performance under high temperature and heavy load environment, suitable for those industrial scenarios that require long-term stable operation.

Self-aligning function: some types of tapered roller bearings have certain self-aligning performance, which can adapt to the axial deviation in the mounting process and reduce the additional wear and bearing fatigue caused by improper mounting.

Separability and interchangeability: the inner and outer rings of tapered roller bearings are usually separable, which makes mounting, dismounting and maintenance more convenient, and also improves the maintenance efficiency.

2. Advantageous features

Long service life: due to its special structural design, tapered roller bearings can effectively reduce friction, noise and vibration, and prolong its service life, especially its durability under high load conditions is excellent.

Low friction and low noise: the precision design of the bearings results in low rolling resistance and reduced noise and vibration during operation, which is particularly important for high-precision machinery and equipment.

High precision and rigidity: Tapered roller bearings have high rigidity and precision, and are suitable for equipment requiring high-precision movement, such as machine tools and precision instruments.

Improvement of equipment efficiency: Due to their good load bearing capacity and long time stable working characteristics, they can improve the overall working efficiency of the equipment and reduce energy consumption.

Product Selling Points

Versatility: The design of tapered roller bearings enables them to provide excellent performance in a variety of complex environments, especially when subjected to mixed loads (both radial and axial loads) is very advantageous.

High Temperature and Wear Resistance: For applications at high temperatures, high speeds or severe operating conditions, the heat and wear resistance of tapered roller bearings ensures their reliability and stability over long periods of operation.

High precision adjustment: By adjusting the fit of the inner and outer rings, the clearance of the bearings can be precisely adjusted, thus ensuring that they can maintain efficient and stable operation under different loads.

Cost-effective: Compared with other types of bearings, tapered roller bearings have a higher cost-effectiveness due to their combined performance in versatility and durability, which makes them especially suitable for high-load applications.

Application Scenarios

Tapered roller bearings are widely used in various industries, especially those fields that require high bearing performance:

Automotive industry: used in automotive drive systems, hubs, transmissions and differentials, capable of withstanding large loads and ensuring smooth operation at high speeds.

Heavy machinery: such as cranes, excavators, construction machinery, etc., can cope with the challenges of high loads and extreme environments.

Aerospace: Tapered roller bearings can provide high-precision running performance in high-precision equipment such as aviation engines.

Mining and metallurgical industries: equipment in these industries is usually subjected to huge loads and harsh working environments, and tapered roller bearings are widely used due to their excellent load capacity and anti-wear performance.

Industry pain points and customer problems

In actual use, customers may face the following common problems:

Excessive wear and damage: Although tapered roller bearings are designed to be robust, if they are used in improper environments or not maintained in a timely manner, they may lead to increased wear or even premature damage.

Excessive vibration and noise: Bearings that are subjected to unsuitable loading conditions for a long period of time may lead to excessive vibration and noise, thus affecting the normal operation of the equipment.

Inappropriate clearance: Improper adjustment of the clearance will affect the performance of the bearing, leading to unstable operation and even early scrapping.

Excessive temperature: Under high temperature environment, the lubrication performance of bearings decreases, which may lead to excessive wear and shorter life.

Solutions and Suggestions

In order to solve the problems faced by customers, the following solutions can be adopted:

Optimize mounting and adjustment:

Ensure the mounting accuracy of the bearings and avoid deviations caused by improper mounting. Especially when subjected to high loads and high speeds, it is critical to adjust the clearance and mounting position of the bearings.

Regularly check the clearance of the bearings to ensure that it is within the appropriate range. Proper adjustment of the clearance using an adjustment tool can extend the service life of the bearings.

Enhance lubrication and cooling:

Add suitable lubricant to the tapered roller bearings at the right time and ensure that the lubricant is clean to avoid particles from entering the bearings and increasing wear.

For high-temperature application scenarios, it is recommended to use high-performance grease and strengthen the design of the cooling system to ensure that the bearings can continue to work stably in high-temperature environments.

Regular maintenance and inspection:

Regular maintenance and inspection of the bearings, especially monitoring the vibration, temperature and load condition of the bearings. Once abnormal signs are found, they should be replaced or adjusted in time.

Under high load conditions, select bearings with appropriate specifications and perform regular maintenance according to the application environment.

Select the appropriate bearing type:

Select the appropriate model of tapered roller bearings according to the load conditions, working environment and accuracy requirements of the actual application. For example, for high load applications, choose bearing models with stronger load carrying capacity, or for high-speed applications, choose models that are adapted to higher speeds.

Summarize

Tapered roller bearings are widely used in many industries due to their excellent load carrying capacity and adaptability to a variety of working conditions. By optimizing installation, adjusting clearance, strengthening lubrication and regular maintenance, bearing life can be effectively extended, equipment performance can be improved, and the common problems encountered by customers in high loads and complex environments can be solved.

Message

Message