Angular contact ball bearings are essential components in various mechanical systems, designed to handle combined radial and axial loads with high efficiency. Their unique design and versatility make them suitable for numerous applications across different industries.Angular

Angular contact ball bearings are essential components in various mechanical systems, designed to handle combined radial and axial loads with high efficiency. Their unique design and versatility make them suitable for numerous applications across different industries.Angular

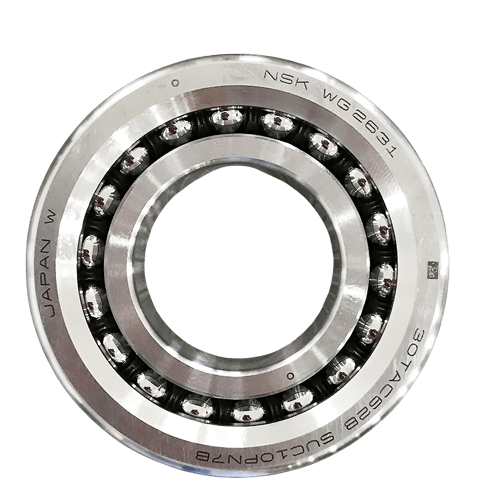

Contact Ball Bearing Characteristics

Occupies less axial space

Can be used in applications where axial space is limited when two single row angular contact ball bearings are arranged back to back .

Product Information and Features

Angular contact ball bearings are characterized by their contact angle, which allows them to support axial loads in one direction and radial loads simultaneously. The contact angle, typically ranging from 15° to 40°, determines the bearing’s axial load capacity—the larger the angle, the higher the capacity. These bearings are available in several configurations:

-

Single Row Angular Contact Ball Bearings: Designed to accommodate axial loads in one direction, often used in pairs to handle bidirectional axial loads.

-

Double Row Angular Contact Ball Bearings: Functionally similar to a pair of single row bearings in a back-to-back arrangement, capable of handling axial loads in both directions and offering high radial stiffness.

-

Four-Point Contact Ball Bearings: Designed to handle axial loads in both directions with a single bearing, thanks to a split inner ring that creates a four-point contact.

These bearings are constructed using various materials, including high-grade steel, ceramic, and hybrid combinations, to suit specific application requirements. They also feature different cage materials, such as brass, steel, or polymer, to enhance performance under varying operational conditions.

Applications Across Industries

The versatility of angular contact ball bearings makes them integral to numerous industries:

-

Automotive Industry: Utilized in vehicle transmissions, wheel hubs, and steering mechanisms, where they manage combined loads and contribute to vehicle stability and performance.

-

Aerospace Sector: Employed in aircraft engines and landing gear assemblies, where they endure high speeds and significant axial loads, ensuring reliability and safety.

-

Machine Tool Industry: Applied in spindle assemblies of lathes and milling machines, providing the precision and rigidity necessary for high-quality machining.

-

Renewable Energy: Used in wind turbine generators, where they handle complex load patterns and contribute to efficient energy production.

Industry Challenges and Solutions

Despite their advantages, angular contact ball bearings face several challenges:

-

High-Speed Performance: In applications like high-speed machining or aerospace, bearings must withstand elevated rotational speeds without compromising performance.

Solution: Utilizing ceramic balls reduces rotational mass and friction, enhancing high-speed capabilities.

-

Load Capacity Optimization: Balancing axial and radial load capacities to meet specific application demands can be complex.

Solution: Selecting bearings with appropriate contact angles and configurations (e.g., tandem or back-to-back arrangements) optimizes load distribution.

-

Thermal Management: High-speed operations can lead to increased temperatures, affecting bearing performance and longevity.

Solution: Implementing advanced lubrication systems and using materials with superior thermal properties help manage heat generation.

-

Contamination and Wear: Exposure to contaminants can lead to premature bearing failure.

Solution: Employing sealed or shielded bearing designs and ensuring proper maintenance practices mitigate contamination risks.

Customization and Specialized Designs

To address specific application requirements, manufacturers offer customized angular contact ball bearings:

-

Material Selection: Using stainless steel or ceramic materials enhances corrosion resistance and performance under extreme conditions.

-

Preload Adjustment: Customizing preload levels improves rigidity and precision in high-accuracy applications.

-

Special Coatings: Applying coatings like titanium nitride increases wear resistance and extends bearing life.

-

Integrated Sensors: Incorporating sensors monitors bearing conditions in real-time, facilitating predictive maintenance strategies.

These tailored solutions ensure that angular contact ball bearings meet the precise demands of diverse applications, enhancing efficiency and reliability.

Conclusion

Angular contact ball bearings are vital components in modern machinery, offering the ability to handle combined loads with high precision and reliability. Their adaptability across various industries underscores their importance in applications requiring both radial and axial load support. By addressing industry-specific challenges through customized designs and materials, these bearings continue to evolve, meeting the ever-changing demands of advanced mechanical systems.

Angular contact ball bearings are essential components in various mechanical systems, designed to handle combined radial and axial loads with high efficiency. Their unique design and versatility make them suitable for numerous applications across different industries.Angular

Angular contact ball bearings are essential components in various mechanical systems, designed to handle combined radial and axial loads with high efficiency. Their unique design and versatility make them suitable for numerous applications across different industries.Angular

Message

Message