Insert Bearings, also known as Y-bearings, are a type of bearing widely used in industry. They are based on sealed deep groove ball bearings of the 62 and 63 series and have a convex outer ring and an extended inner ring usually equipped with a specific locking device for quick mounting on the shaft.

Insert Bearings, also known as Y-bearings, are a type of bearing widely used in industry. They are based on sealed deep groove ball bearings of the 62 and 63 series and have a convex outer ring and an extended inner ring usually equipped with a specific locking device for quick mounting on the shaft.

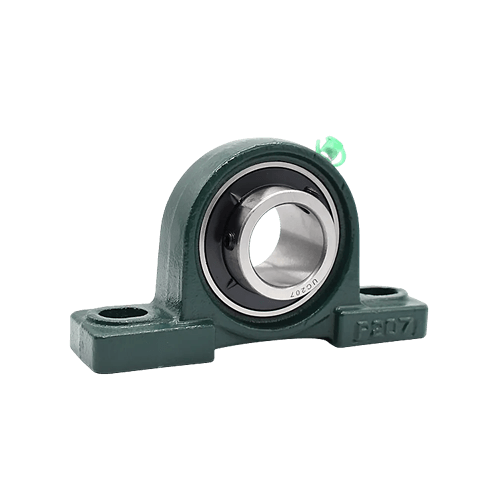

Pillow Block Bearings (Y Bearings)

- Fast and easy installation

Different locking methods allow the mounted bearing to be quickly and easily installed on the shaft. - Capable of accommodating initial misalignment

The spherical outer surface accommodates initial static misalignment caused by seat - Long service life

Different sealing solutions ensure long service life in various applications with high contamination levels.

- Reduced noise and vibration levels

When noise and vibration levels are at a higher level, SKF can provide suitable shaft locking methods.

Insert Bearings description

Insert bearings consist of an inner ring, an outer ring, rolling elements and a cage, and are designed to be self-aligning to accommodate initial misalignment of the shaft. Its outer ring has a spherical shape and the inner ring is usually equipped with different locking methods, such as eccentric locking, screw locking or spring locking, to meet different mounting requirements.

IHB

Advantages and features

Quick mounting: The various locking methods enable the insert bearing to be mounted on the shaft quickly and easily, reducing mounting time and costs.

Self-aligning capability: The spherical outer ring design allows the bearing to adapt to the initial misalignment of the shaft, reducing the requirement for shaft alignment and extending the life of the bearing and associated components.

Variety of sealing solutions: A variety of sealing solutions are available for highly contaminated environments, ensuring that the bearings can still operate stably under harsh conditions.

High load carrying capacity: able to withstand heavy loads and high speeds to meet the needs of various industrial applications.

Application Scenario

Insert bearings are widely used in a variety of equipment in agricultural machinery, construction equipment, food processing, mining and other industries, such as:

Agricultural machinery: used in seeders, harvesters and other equipment to withstand heavy loads and harsh working environments.

Construction equipment: in excavators, bulldozers and other heavy machinery to provide stable support and operation.

Food processing: used in conveyor belts, mixers and other equipment to meet the requirements of hygiene and efficient operation.

Mining industry: in mining equipment, to withstand high loads and harsh working conditions, to ensure the reliability of the equipment.

Industry pain points and solutions

Highly contaminated environments: In highly contaminated environments, bearings are susceptible to dust and moisture, leading to failure.

Solution: A variety of sealing solutions, such as rubber seals and labyrinth seals, are used to prevent contaminants from entering the interior of the bearings and prolong service life.

I

High shaft alignment requirements: Traditional bearings have strict shaft alignment requirements and are complicated to install.

Solution: Insert the self-aligning function of the bearing to allow some misalignment of the shaft, which simplifies the installation process and reduces the requirement for shaft alignment.

High load and high speed: Under heavy load and high speed conditions, bearings are prone to overheating and wear.

Solution: Insert bearings are designed with high load capacity to withstand heavy loads and high rotational speeds to ensure stable equipment operation.

Message

Message