Product Features and Advantages of Screw Bearings and Guideways

Screw bearings and guide rails are an important part of precision mechanical transmission systems, which are widely used in CNC machine tools, automation equipment, robots and other fields. Their main function is to realize smooth and precise linear motion to ensure high precision and high efficiency operation of equipment. The following are their main features and advantages:

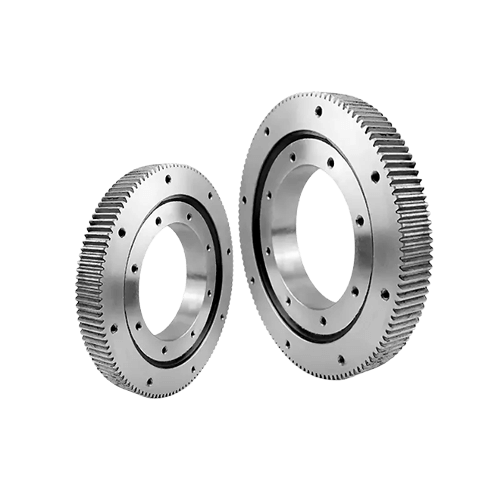

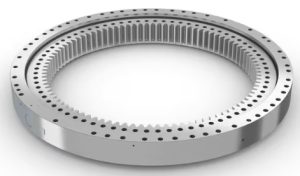

1. Features and advantages of screw bearings

High-precision transmission: Screw bearings realize precise linear motion through the interaction of screws and nuts, which can meet extremely high precision requirements. Its high-precision machining process and material selection ensures precise pitch and rigidity, enabling it to withstand large loads and stable operation.

Low friction and high efficiency: the screw bearing adopts rolling friction mode, which has lower friction coefficient compared with sliding friction, thus reducing energy loss and improving transmission efficiency.

Long service life: Through reasonable lubrication and good material selection, the screw bearing has a long service life. High-quality bearings can effectively reduce wear and prolong the service life of the equipment.

High load carrying capacity: Screw bearings can withstand large axial and radial loads, suitable for work under high load conditions, and can operate stably in harsh environments.

2. Features and advantages of linear guide

High rigidity and stability: linear guide can provide very high rigidity, reduce the deformation caused by the load change, so as to ensure the long-term efficient operation of mechanical equipment.

Low friction and high precision: rolling elements in the guide system (such as ball) can significantly reduce the coefficient of friction to ensure smooth operation of the system. The precision and smoothness of the guideway directly affects the overall performance of the equipment.

Automatic Adjustment Function: Many guideway systems adopt the centering design, which can automatically adapt to the shaft deviation caused by assembly errors, temperature changes and other factors, thus reducing the wear of bearings and guideways and prolonging the service life.

Easy maintenance: Modern linear guideway designs are often equipped with automatic lubrication systems, simplifying routine maintenance and improving equipment availability.

Application scenarios for screw bearings and guideways

Screw bearing and guideway systems have a wide range of applications in several industries, and are particularly important in the following areas:

CNC machine tools: In machine tools, the screw bearings take on the task of transmitting power and precise positioning to ensure that the machine tool is capable of precision machining. At the same time, the guideway system ensures smooth sliding and high rigidity of the moving parts of the machine tool.

Automated production lines: Automated equipment requires precise and stable transmission systems. Screw bearings and guideways provide high precision and long-time reliability, adapting to high-load and high-speed working environments.

Robotics: The movement of robot joints requires high-precision, high-rigidity transmission devices, and screw bearings and guideway systems ensure precise and smooth robot movements.

Aerospace and Precision Instruments: Equipment in these industries often requires very high precision and stability, and screw bearings and guideways provide the ideal solution to ensure precision and long-term operational stability.

Industry pain points and the current problems faced by customers

Although screw bearings and guide rails are widely used in many industries, there are still some industry pain points and challenges faced by customers in the actual application process:

1. Wear and tear due to high loads

As the load of industrial automation equipment increases, screw bearing and guideway systems are often faced with large axial and radial loads, which leads to increased wear and tear, thus affecting the accuracy and service life of the equipment.

2. Impact of environmental pollution on the system

In some harsh working environments, such as high temperature, high humidity or dusty environments, screw bearings and guideways are susceptible to external environmental aggression, poor lubrication and contaminants into the system will accelerate wear.

3. Challenge of high precision requirement

With the industry’s increased demand for precision, the existing screw bearing and guideway system is faced with the challenge of how to work stably under higher precision conditions. Especially in high-speed, high-precision applications, any small error may affect the quality of the final product.

4. Lubrication and maintenance issues

Although modern screw bearings and guideways are often equipped with automatic lubrication systems, a faulty or improperly maintained lubrication system can still lead to increased friction, higher temperatures and system failures, affecting the long-term stability of the equipment.

Solutions and Suggestions

In order to solve the above pain points, enterprises can take the following measures:

1. Select high-performance materials and coating technology

The use of high-performance materials such as ceramic coatings, stainless steel, etc. can effectively improve the wear resistance and corrosion resistance of screw bearings and guide rails, especially in high-temperature or more polluted environments, which can significantly extend the service life of the equipment.

2. Optimize the lubrication system

Regularly check and optimize the lubrication system, using more efficient lubricant or grease to reduce friction, reduce temperature and extend the service life of bearings and guide rails. In addition, for high load, high speed applications, consider using automatic lubrication or oil mist lubrication system.

3. Improve precision and rigidity

In the design and production process, improve the manufacturing accuracy of screw bearings and guide rails, adopt high-precision machining technology and strict quality control measures to ensure that the products can meet higher accuracy requirements, especially in precision machining and high-precision equipment.

4. Regular maintenance and repair

In order to ensure the long-term stable operation of screw bearings and guide rails, it is recommended to formulate a regular maintenance program to inspect, clean and lubricate the products, promptly troubleshoot potential problems and prevent failures caused by improper maintenance.

5. Intelligent and data monitoring

With the development of industrial Internet, real-time monitoring of screw bearings and guide rails combined with sensor technology and intelligent monitoring system can identify equipment failures in advance, carry out preventive maintenance, and avoid downtime and losses caused by failures.

Conclusion

Screw bearings and guideways play a crucial role in modern mechanical systems, especially in high-precision, high-load applications. Although there are still some industry pain points, such as wear and tear, environmental impact, precision requirements and maintenance issues, by adopting high-performance materials, optimizing lubrication systems, improving production accuracy, strengthening maintenance and repair, and introducing intelligent monitoring, companies can effectively improve the stability, precision and service life of equipment, providing strong technical support for the development of the industry.

Message

Message