-

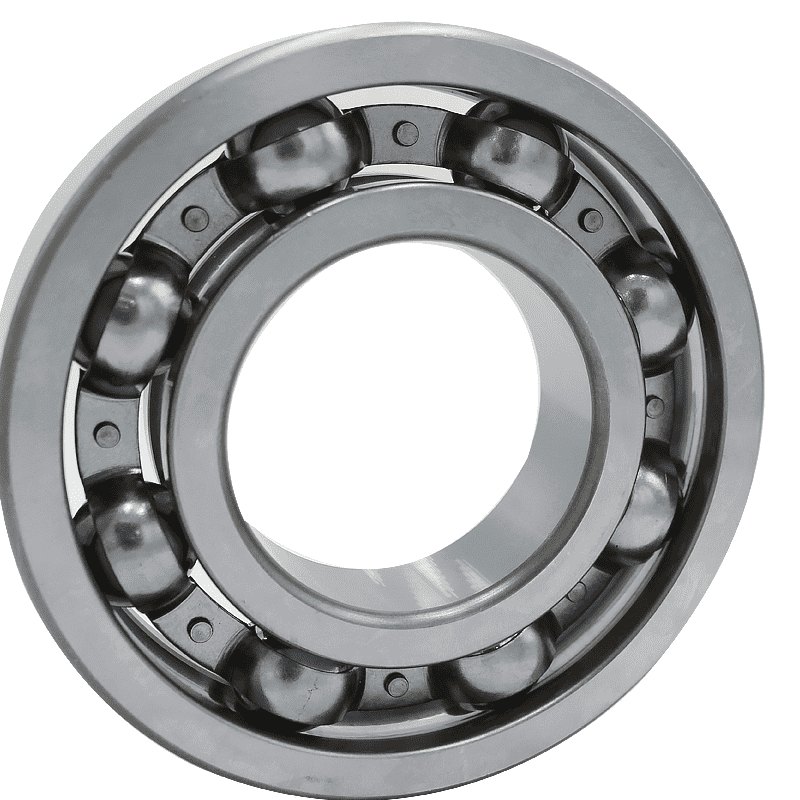

Low Friction and High-Speed Capability: The precise design of deep groove ball bearings ensures minimal friction, enabling high-speed performance. This characteristic is particularly beneficial in applications requiring rapid rotational speeds, such as electric motors and automotive components.

-

Load-Bearing Versatility: These bearings can accommodate radial loads (perpendicular to the shaft) and axial loads (parallel to the shaft) in both directions. This dual-load capacity enhances their adaptability across various applications, from household appliances to industrial machinery.

-

Ease of Installation and Maintenance: The straightforward design of deep groove ball bearings simplifies installation and reduces maintenance requirements. Their durability and reliability contribute to lower operational costs over time.

Customization and Specialized Designs

While standard deep groove ball bearings meet the needs of many applications, certain scenarios demand customized solutions to achieve optimal performance. Manufacturers offer various customization options, including:

-

Special Materials: Utilizing materials such as stainless steel or ceramic can enhance corrosion resistance, reduce weight, or improve high-temperature performance, depending on the application’s requirements.

-

Sealing Options: Custom seals can be designed to protect the bearing from contaminants like dust and moisture, thereby extending its service life.

-

Pre-Lubrication: Bearings can be supplied with specific lubricants tailored to the operating conditions, ensuring optimal performance from the outset.

-

Dimensional Adjustments: Modifying the bearing’s dimensions allows for integration into unique machinery designs where standard sizes may not be suitable.

These customizations enable deep groove ball bearings to meet specialized performance requirements, enhancing efficiency and longevity in challenging environments.

Applications Across Industries

The versatility of deep groove ball bearings makes them integral components in numerous industries, including:

-

Automotive: Used in gearboxes, engines, and wheel hubs to ensure smooth and reliable operation.

-

Industrial Machinery: Applied in conveyors, pumps, and compressors where both radial and axial load support is essential.

-

Consumer Electronics: Found in fans, hard drives, and other devices requiring quiet and efficient rotation.

-

Household Appliances: Utilized in washing machines, vacuum cleaners, and other appliances to facilitate smooth motor function.

Conclusion

Deep groove ball bearings are indispensable in modern machinery, offering a combination of low friction, high-speed capability, and load-bearing versatility. Their ease of installation and low maintenance further contribute to their widespread adoption. For applications with unique performance demands, customized deep groove ball bearings provide tailored solutions that enhance functionality and durability.

Message

Message