Thrust ball bearings are a kind of mechanical parts specially designed to bear axial load, widely used in all kinds of mechanical equipment.

Thrust ball bearings are a kind of mechanical parts specially designed to bear axial load, widely used in all kinds of mechanical equipment.

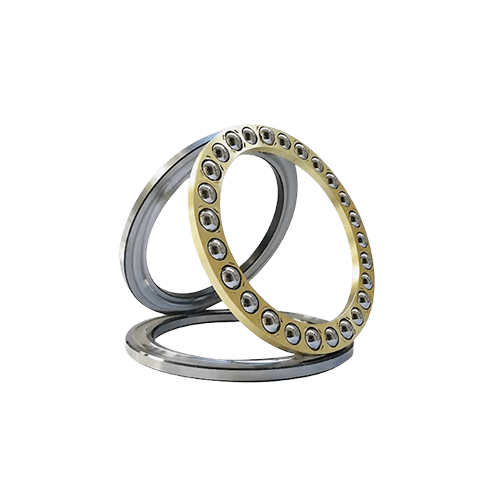

Thrust ball bearings

Product introduction and structure

Thrust ball bearings are mainly composed of the following parts:

Seat ring (seat ring): fixed in the bearing seat, to provide support.

Axle ring (shaft ring): connected with the shaft, bear axial load.

Rolling body (ball): located between the seat ring and shaft ring, responsible for carrying axial load.

Cage: Used to keep the rolling elements apart and prevent them from coming into contact with each other.

According to the direction of load bearing, thrust ball bearings can be divided into two types: unidirectional and bidirectional.

Second, the advantages and characteristics

High load carrying capacity: able to withstand large axial load, to ensure stable operation of equipment.

Low coefficient of friction: design optimization to reduce friction and improve operation efficiency.

Easy maintenance: simple structure, easy to install and maintain.

Strong adaptability: applicable to a variety of working environments and conditions.

Third, the application scene

Thrust ball bearings are widely used in the following fields:

Heavy machinery: such as excavators, cranes, etc., bearing huge axial load.

FHD bearings

Automobile industry: used in automobile transmission system to ensure smooth operation.

Aerospace: in aircraft engines and other key components, to provide reliable axial support.

Industrial equipment: such as pumps, compressors, etc., to ensure the efficient operation of equipment.

Fourth, the industry pain points and solutions

In practical applications, thrust ball bearings may face the following challenges:

Insufficient lubrication: leading to increased friction and shortened service life.

Contaminant intrusion: External contaminants enter the bearing, affecting performance.

Overloaded operation: Exceeding the design load carrying capacity, leading to failure.

The following measures are recommended to address these issues:

Regular lubrication: Use appropriate lubricants to keep the bearings well lubricated.

Seal protection: Adopt effective sealing measures to prevent pollutants from entering.

Reasonable selection: According to the actual working conditions, select the appropriate bearing type to avoid overload operation.

Through the above measures, the performance and service life of thrust ball bearings can be effectively improved to meet the high requirements of various industries for equipment reliability.

Message

Message