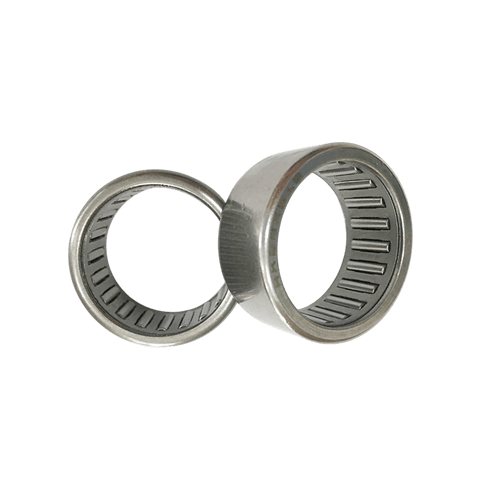

Needle Roller Bearings

As an important mechanical element, needle roller bearings are widely used in various types of high-precision, high-load industrial equipment. Its core feature lies in the use of needle rollers as rolling bodies, which has the advantages of compact structure and high load carrying capacity. In order to help understand the product characteristics, advantages and selling points of needle roller bearings, we will analyze in detail from a variety of perspectives, and combined with the actual application scenarios and industry pain points, to put forward specific solutions and recommendations.

First, the product characteristics of needle roller bearings

Needle roller bearings and other types of rolling bearings, its biggest feature is the use of long and thin needle as a rolling body. Compared with the round ball roller, the contact area of needle roller is greatly increased, which makes it has higher load carrying capacity and stronger durability.

High load carrying capacity: Due to the elongated shape of the needle rollers, they are able to provide a larger contact area under the same size, therefore, needle roller bearings have a higher radial load carrying capacity.

Compact structure: needle roller bearings have a very compact structure and can provide a larger load capacity under the same bearing size, which is especially suitable for application scenarios with limited space.

Low friction characteristics: needle roller bearings have low friction and therefore can improve the operating efficiency of the system and reduce energy loss.

High precision and durability: it adopts precision machined needle roller and outer ring, which can ensure high running accuracy, suitable for the needs of high-precision machinery.

Second, the advantages and characteristics of needle roller bearings

The advantages of needle roller bearings are very obvious, especially in certain high-load, high-precision application areas, its advantages are more prominent.

Adapt to harsh environment: due to its strong resistance to high temperature, corrosion and pollution, needle roller bearings can still maintain efficient operation in complex working environment. For example, needle roller bearings are widely used in automobiles, agricultural machinery, oil and gas equipment and other fields.

High load and long life: Needle roller bearings are able to provide excellent performance in occasions where they are required to withstand large radial loads and certain axial loads. At the same time, its durability is good, which can extend the service life of the equipment.

High speed and low noise: in the case of high-speed operation, the low friction characteristics of needle roller bearings can effectively reduce noise and vibration, suitable for precision instruments and high-speed motors and other equipment.

Flexibility and customizability: needle roller bearings can be customized according to different application requirements, providing a variety of different forms and sizes to meet the individual needs of customers.

Third, the product selling points of needle roller bearings

Space optimization: Due to its compact structure, needle roller bearings can provide higher load capacity in limited space. This is particularly important for space-constrained equipment (e.g. gearboxes, transmissions, etc.).

Cost-effective: Compared to other types of bearings, needle roller bearings are a cost-effective alternative because of their relatively low manufacturing costs and excellent performance.

Wide range of applications: Needle roller bearings are used in a wide range of applications, from automotive and aerospace to precision machinery, medical equipment and many other fields.

Low maintenance requirements: its durability and long life, can effectively reduce equipment downtime and maintenance costs, improve the reliability of the overall equipment.

Fourth, application scenarios and industry pain points

Application scenarios:

Precision machinery: needle roller bearings are widely used in high-precision mechanical equipment, such as CNC machine tools, optical instruments, robot joints, etc..

Automobile industry: in the engine, transmission, drive shaft and other key components, needle roller bearings ensure the smooth operation of power transmission through high load bearing capacity.

Agricultural machinery: in agricultural machinery (such as tractors, harvesters, etc.), needle roller bearings are widely used because of their high load resistance and anti-pollution characteristics.

Industrial equipment: in a variety of heavy equipment (such as reducers, fans, compressors, etc.), needle roller bearings can provide efficient performance.

Industry pain points:

Insufficient equipment load: Many industrial equipment is subjected to heavy or high-precision loads, but conventional bearings are prone to wear in these extreme environments, affecting the performance and life of the equipment.

Space constraints: In many machinery and equipment, the use of large bearing sizes is impractical due to space constraints, so compact and efficient bearing solutions need to be found.

High friction and low efficiency: Some equipment operates at high speeds with excessive friction, leading to inefficiencies and increased energy consumption.

High Maintenance Costs: The harsh environments of some applications result in bearings that are prone to damage, resulting in frequent repairs and replacements and increased operating costs.

V. Solutions and Suggestions

Choose the right model: According to the specific application scenarios and load requirements, enterprises need to choose the right needle roller bearing model. For example, for high load working environment, you can choose the type with stronger bearing capacity; and in high-speed applications, you should choose the needle roller bearings with less friction and higher precision.

Optimized mounting and maintenance: Since needle roller bearings require a high degree of mounting accuracy, it is necessary to ensure correct mounting. Too high or too low preload may lead to premature bearing failure and reduce its service life. In terms of maintenance, the lubrication status of the bearings should be checked regularly and the contaminants in the bearings should be cleaned in time to ensure the best working condition of the bearings.

Technical improvements for industry pain points:

High load design: For equipment that needs to bear heavy loads, reinforced needle roller bearings can be used to improve their load carrying capacity by increasing the number of needle rollers or material strength.

Protective design: In harsh working environments, dust-proof, water-proof and corrosion-proof needle roller bearings should be used to avoid the deterioration of bearing performance caused by external factors.

Innovation and customized solutions: According to the specific needs of customers, the bearings can be customized to meet the requirements of precision, speed, load and so on under their specific working conditions.

By comprehensively considering the product characteristics, advantages and pain points in the actual application of needle roller bearings, we can provide customers with effective technical support and solutions to ensure the efficient and stable operation of the equipment, reduce maintenance costs and extend the service life of the products.

Sixth, summarize

Needle roller bearings have been widely used in various industries due to their excellent load carrying capacity, compact structure, low friction characteristics and wide applicability. However, in the face of various pain points in the industry, such as high loads, space constraints, friction and maintenance problems, choosing the right needle roller bearings and carrying out reasonable design and installation can effectively improve the performance of the equipment and reduce operating costs. For manufacturers, customized service and technical support will be the key to solving industry pain points.

Message

Message