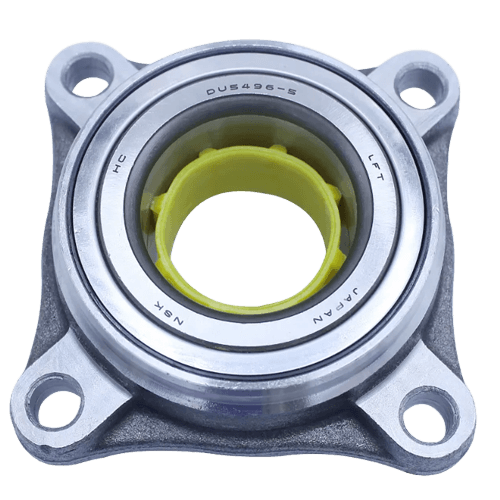

Wheel Hub Bearing

Product Characteristics of Hub Bearings

Hub Bearings are key components in automobiles and other transportation vehicles, mainly used to support wheels and ensure their smooth rotation. Modern hub bearings not only have the basic function of carrying axial and radial loads, but also have the ability to integrate a variety of additional functions to adapt to different working environments and high load requirements. Wheel bearings usually consist of an inner ring, an outer ring, rolling elements (e.g. steel balls or rollers), a cage and seals, and their structural design is crucial to enhancing the safety, comfort and efficiency of the vehicle.

High Load Carrying Capacity: Wheel bearings can withstand high intensity radial and axial loads, ensuring stable operation of the vehicle under various driving conditions.

Sealing performance: Many modern wheel bearing designs have integrated sealing functions that can effectively prevent the intrusion of external contaminants such as water, dust, salt, etc., reduce lubricant leakage, and extend bearing life.

Low friction and high temperature resistance: The use of high performance grease and high temperature resistant materials reduces the coefficient of friction, improves operating efficiency, reduces energy consumption, and maintains long term operational stability.

Integrated design: Wheel bearings integrate multiple components through integrated design, simplifying installation and maintenance and improving system reliability and economy.

Advantages of wheel bearings

Improvement of automobile safety: Wheel bearings can effectively share the load of tires and wheel parts, reduce the friction when the wheels are rotating, thus improving the braking efficiency and stability, and reducing the shaking or loss of control of the car caused by uneven friction.

Extended service life: Due to their high sealing, wheel bearings can prevent the intrusion of dust and moisture, which greatly reduces the impact of contamination on bearing life. At the same time, the high quality of the bearing steel and the design of the lubrication system result in high load carrying capacity and long life, especially in harsh environments.

Reduced Maintenance Costs: The integrated design of the wheel bearing reduces the number of parts and simplifies installation and maintenance. The self-lubricating design reduces the need for frequent grease additions and reduces maintenance costs, making it particularly suitable for long-distance transportation vehicles and high-frequency use.

Enhanced Comfort: Due to their design to reduce friction and noise, wheel bearings provide a smooth driving experience and reduce vehicle noise and vibration during driving, thus enhancing passenger comfort.

Wheel bearing application scenarios

Wheel bearings are widely used in the following major fields:

Automotive industry: Wheel bearings are one of the core components in modern automobiles, especially commercial vehicles, luxury vehicles and sports cars. Its main function is to ensure smooth rotation of the wheel and enhance the driving safety, stability and fuel economy of the car. Especially under the conditions of high load and long time high speed driving, the performance of wheel bearings is crucial.

Electric Vehicles (EVs): With the rise of electric vehicles, wheel bearings are facing new challenges. EVs often require higher efficiency and lower energy consumption, so the low-friction characteristics and durability of wheel bearings become especially important.

Commercial Vehicles and Heavy Machinery: In commercial vehicles and construction machinery, wheel bearings not only need to withstand higher loads, but also operate in extreme environments, such as high temperatures, high loads, and continuous operation under complex road conditions.

Customer Problems and Pain Points

Impact of high loads and extreme environments on bearings: When commercial vehicles and heavy vehicles operate under high loads or extreme environments, wheel bearings are often exposed to high temperatures, high humidity, dust and other environmental factors, which can easily lead to bearing damage, oil leakage and excessive friction, and in serious cases, may cause traffic accidents.

Complicated installation and adjustment: As traditional wheel bearings need to be finely adjusted according to the vehicle model, load requirements and operating environment, the installation process is cumbersome and prone to errors, which may lead to bearing performance degradation or even premature failure.

High maintenance costs: In many vehicles, once a wheel bearing is damaged, it is often necessary to replace the entire bearing unit instead of repairing it partially. This not only increases parts costs, but also increases labor intensity and repair time.

Inconsistent performance: Due to product quality variations among manufacturers, wheel bearings may not perform consistently over long periods of time under high loads, and may run out, overheat, or fail, affecting driving safety.

Solutions and Recommendations

Use high sealing and durable materials: For applications in extreme environments, wheel bearings with higher sealing, high temperature and corrosion-resistant materials and designs can be used to extend the life of the bearings and improve reliability.

Integrated design and modular solutions: Hub bearing units are available in an integrated design that reduces mounting complexity and ensures precise alignment and fit. In addition, the modularized design allows customers to select different configurations of wheel bearings according to actual needs to improve applicability and convenience.

Intelligent monitoring technology: Promote intelligent monitoring system to monitor the temperature, vibration and wear status of wheel bearings in real time. Through data analysis, potential failures can be forewarned in advance to avoid more serious losses due to sudden bearing damage.

Optimize maintenance programs: For high-load applications, it is recommended that bearings be inspected and lubricated on a regular basis, and damaged parts be replaced in a timely manner. In addition, automatic lubrication systems can be introduced to reduce manual intervention and maintenance costs.

Enhance technical training and support: For customers, especially mass transportation companies and commercial vehicle users, professional technical training and after-sales support are provided to help them better understand the maintenance and optimize the use of wheel bearings, and improve the efficiency and life of bearings.

Adoption of Innovative Designs: To develop high-efficiency, low-friction and long-life wheel bearings suitable for electric vehicles to meet the needs of high-efficiency and long-distance traveling of electric vehicles.

Summary: Wheel bearings are a key automotive component.

As a key automotive component, wheel bearings play a vital role in ensuring vehicle safety, comfort and performance. Technological innovation in the wheel bearing industry is particularly important as market demand for efficient, cost-effective and highly reliable products increases. Through the introduction of new materials, intelligent monitoring and optimized design, current industry pain points can be effectively addressed to enhance product competitiveness and meet customer needs.

Message

Message