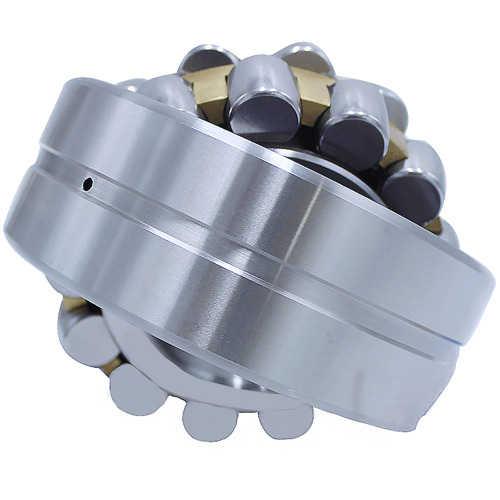

Spherical Roller Bearing

Spherical roller bearings are a kind of rolling bearings with self-aligning function, which are widely used in mechanical equipments that need to bear large radial load and medium axial load.

Product Description of Spherical Roller Bearings

Spherical roller bearings are composed of inner and outer rings, the inner ring has two spherical raceways tilted to the axis, the outer ring is spherical raceway, the rollers are cylindrical or drum-shaped, usually equipped with cage. Its unique design enables it to automatically adjust the angular deviation caused by the mounting error between the shaft and the housing or the bending of the shaft to ensure that the bearing always maintains a good contact state during the working process.

Spherical Roller Bearing Structure

The main structural features of spherical roller bearings include:

Inner ring: with two spherical raceways inclined to the axis, providing the running track of the rollers.

Outer ring: a spherical raceway, allowing the inner ring and rollers to self-align within a certain angle.

Roller: Usually cylindrical or drum shaped to carry radial loads.

Cage: Used to maintain an even spacing between the rollers and prevent collisions between the rollers.

Advantages and features

Spherical roller bearings have the following advantages and features:

Self-aligning ability: able to automatically compensate for angular deviation caused by mounting error or shaft bending, reducing the requirement for mounting accuracy.

High load carrying capacity: suitable for applications subject to large radial loads and medium axial loads.

Durability: Due to its structural design, it is able to operate stably for a long period of time under adverse working conditions.

Application Scenarios

Spherical roller bearings are widely used in the following fields:

Machinery manufacturing: used in machine tools, cranes and other equipment to withstand heavy loads and shock loads.

Metallurgical machinery: in high temperature, high load environment, to ensure the stable operation of equipment.

Automobile industry: used in automobile drive axles, wheel hubs and other components to withstand complex loads.

Mining machinery: Provide reliable support under harsh working conditions.

Industry pain points and solutions

In practical applications, spherical roller bearings face the following challenges:

High-temperature environment: Under high-temperature conditions, bearing lubricants may fail, leading to bearing damage.

Contaminant intrusion: Contaminants such as dust and sewage may enter the bearing and affect its performance.

High-load shock: Under heavy loads and shock loads, bearings may experience fatigue damage.

In response to these problems, the industry has proposed the following solutions:

Use of high-temperature lubricants: Adopt high-temperature resistant lubricants to ensure the normal operation of bearings in high-temperature environments.

Optimization of sealing design: Improve the sealing structure of bearings to prevent the entry of contaminants.

Material improvement: adopt high strength and wear-resistant materials to improve the bearing capacity and durability of the bearings.

Through the above measures, the performance of spherical roller bearings can be effectively improved to meet the requirements of various industries for equipment reliability.

》》Why you need to know more and choose high quality Spherical Roller Bearing

Click to learn more about valuable business

Message

Message