ABOUT US

AFUTAI(JI NING) BEARING MANUFACTURER CO.,LTD

AFUTAI(JI NING) BEARING MANUFACTURER CO.,LTD was established in 2008 and is located in JI NING City,Shan Dong Province,China.and enjoys the reputation of "Hometown of Confucius"enjoying convenient transportation and beautiful environment.covers an area of 15000 square meters and has about 200 employees.has been engaged in bearing export trade for more than 16 years with rich experience.has automatic heat treatment line, injection molding machine, noise detection, roundness testing, vacuum sintering furnace these equipment, etc, and can produce the bearings which can meet your requirement.

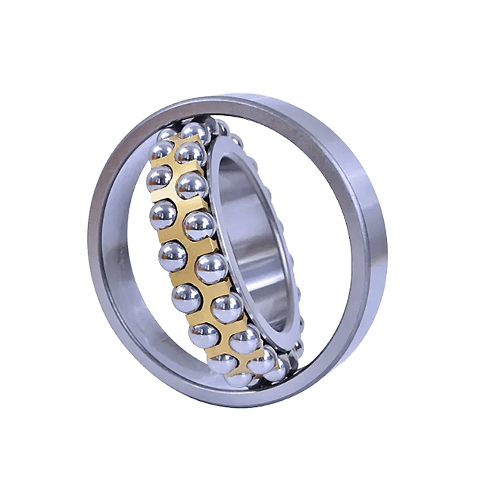

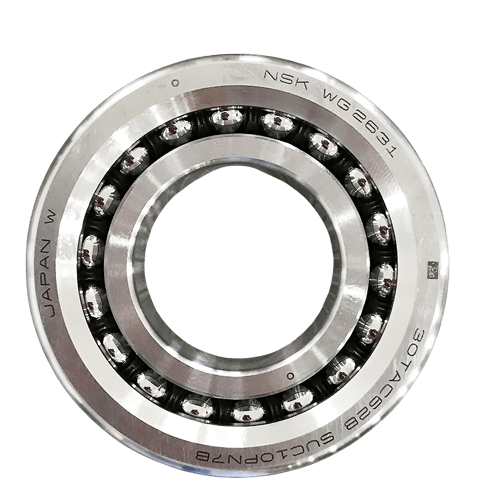

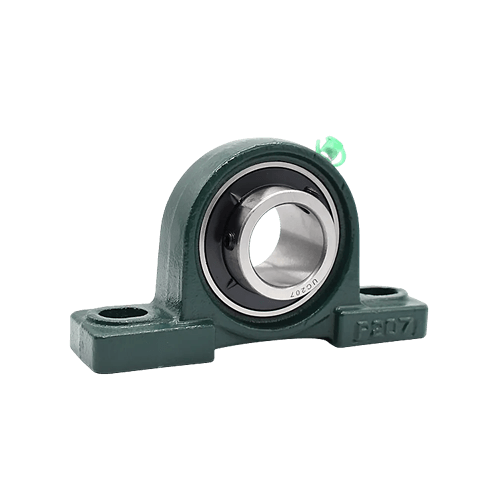

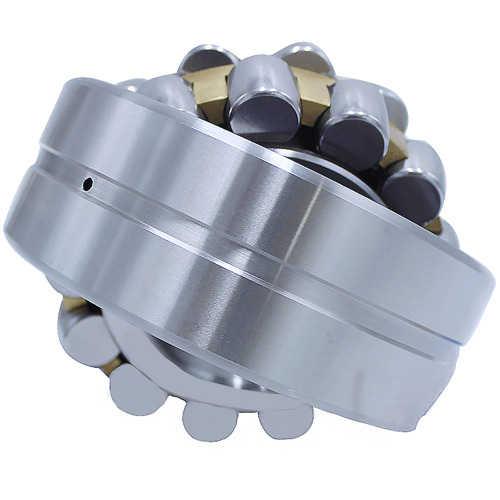

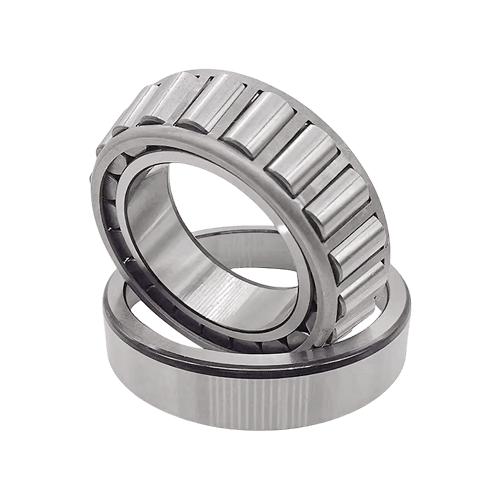

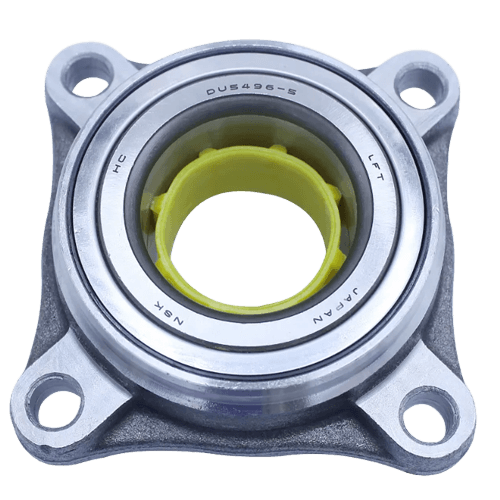

Our main products include ball bearings,roller bearings,linear bearings,linear guide,truck, automotive tapered roller bearing, wheel hub bearing, clutch release bearing, etc.export products to USA, Brazil, Russia, Saudi Arabia, Vietnam, Venezuela, South Africa, UAE, Egypt, and other countries,gain wide praises at home and abroad. we also support OEM and ODM orders, whether the current product from our catalog or seeking engineering assistance for your application, you can contact our customer service center to talk about your sourcing requirements.

More