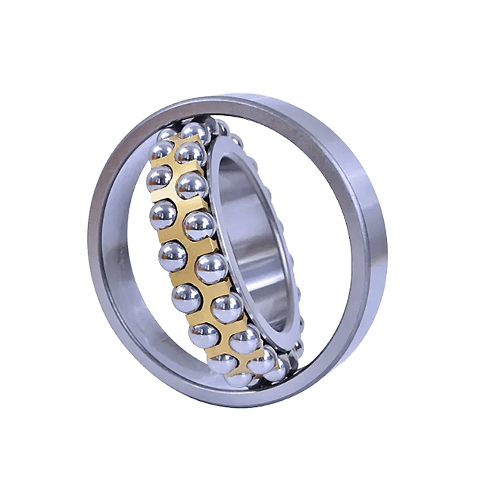

Self-aligning ball bearings

Design and Construction

These bearings feature two rows of balls with a common spherical outer raceway. This design allows the inner ring, along with the balls, to pivot freely, compensating for angular misalignments typically up to 3 degrees. The internal architecture minimizes friction and enables the bearing to maintain performance under varying alignment conditions.

Key Features and Benefits

-

Misalignment Accommodation: The spherical outer raceway permits self-alignment, effectively handling both static and dynamic misalignments without compromising performance.

-

Reduced Friction and Heat Generation: The design ensures minimal friction, allowing the bearings to operate at cooler temperatures even at high speeds, which enhances efficiency and prolongs service life.

-

Versatile Bore Options: Available with cylindrical or tapered bores, these bearings can be easily mounted using adapters, providing flexibility across different applications.

-

Noise and Vibration Reduction: Self-aligning ball bearings contribute to lower noise and vibration levels, making them suitable for applications where operational quietness is essential.

Applications Across Industries

The adaptability of self-aligning ball bearings makes them suitable for a wide range of applications, including:

-

Industrial Machinery: Ideal for equipment where shaft deflection or misalignment is common, ensuring reliable performance and longevity.

-

Agricultural Equipment: Used in machinery exposed to harsh conditions, where alignment issues are prevalent.

-

Fans and Blowers: Their ability to reduce noise and vibration makes them suitable for high-speed fans and blowers.

-

Textile Machinery: Employed in equipment requiring high-speed operation with minimal maintenance.

Customization and Specialized Designs

Manufacturers offer various customization options to meet specific application requirements:

-

Sealed Versions: Sealed self-aligning ball bearings provide protection against contaminants, extending service life in challenging environments.

-

Material Choices: Options include bearings made from stainless steel or other specialized materials to enhance corrosion resistance or performance under specific conditions.

Conclusion

Self-aligning ball bearings are essential components in modern machinery, offering the unique ability to compensate for misalignment while maintaining low friction and high-speed capabilities. Their versatility across various industries underscores their importance in applications where reliability and efficiency are paramount.

The following are examples of applications where self-aligning ball bearings can be used:

-

- Industrial fans

- agriculture

- Material Transportation

- Food & Beverage

- Pulp and paper industry

》》Why you need to know more and choose high quality Self-Aligning Ball Bearings

Click to learn more about valuable business

Message

Message